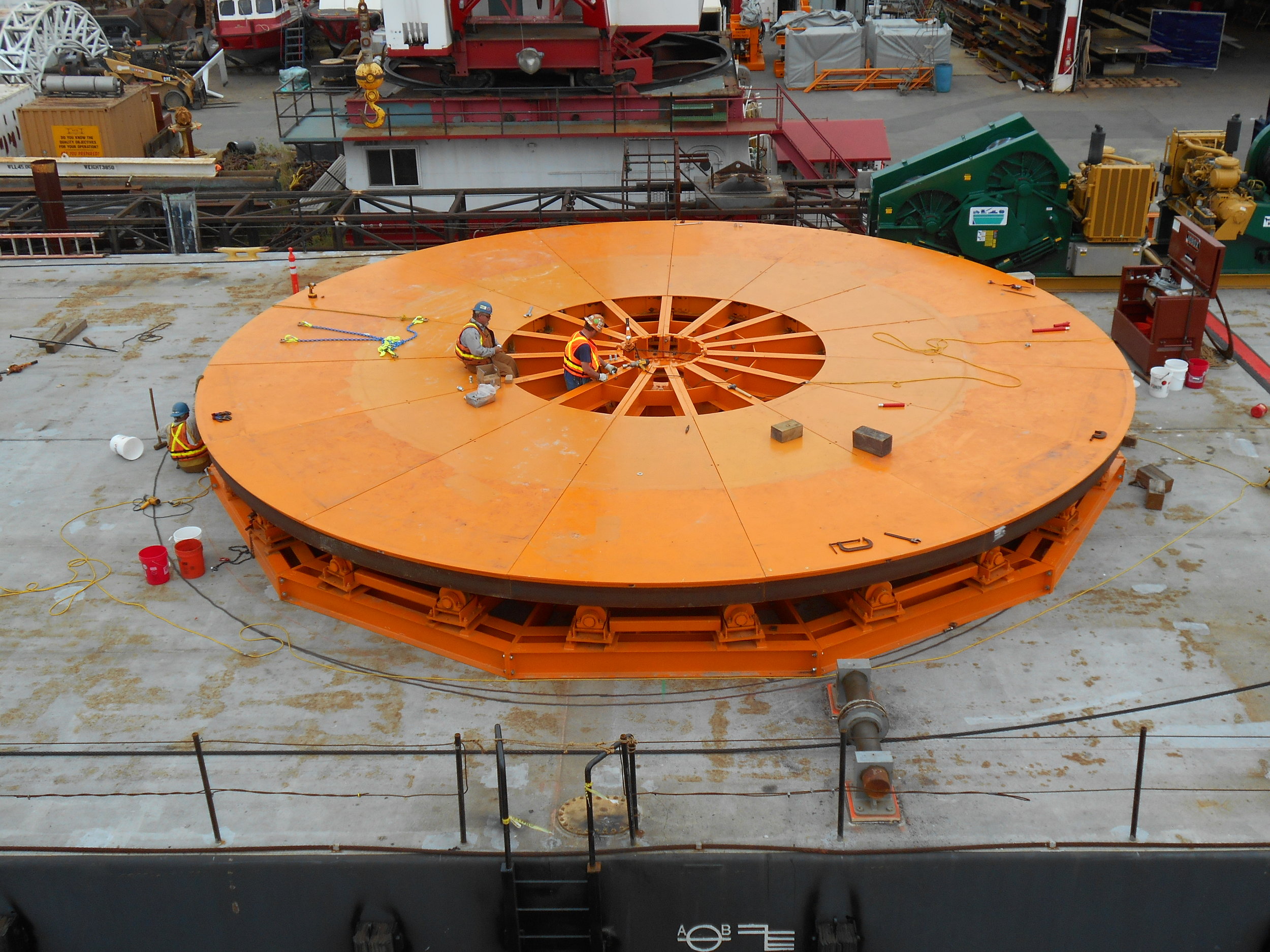

Macton Corporation engineers, fabricates and installs high quality Car Hoist and Hoist systems for the transit rail market. This is our equipment hoisting the VTA (Valley Transportation Authority) in San Jose. In Addition to Macton Corporation’s Car Hoist and Hoist systems, we manufacture Portable Electric Jacks, Truck Hoist, Truck Rotators, Wheel Truck Turntables, Drop Tables, Split Rail Trolley Systems, Portable Sanding Trailers, Transfer Tables and Accessories for the Rail Maintenance market.

Macton's confidence in its products has been proven time and again and we want our customers to know we stand behind our products and the quality that goes into them. Macton is proud of the experience and craftsmanship that goes into each and every product we sell. As part of its commitment to quality, Macton is offering a 5 year standard warranty on all of its products.

Macton sought ISO certification as part of its ongoing efforts at continuous improvement in its product quality and ongoing operations and as a result is now ISO 9001:2015 certified.

All of Macton’s electrical panels meet the applicable UL 508A (Industrial Control Equipment) standards (as well as CAN/CSA 22.2 No. 14 standards), and are labeled to show that they have been certified by TUV Rheinland as meeting those standards (certificate # 0000019219).

Everything manufactured in the USA! Go America. Go Macton.

Read More