Rail and Transit Systems – Truck Removal

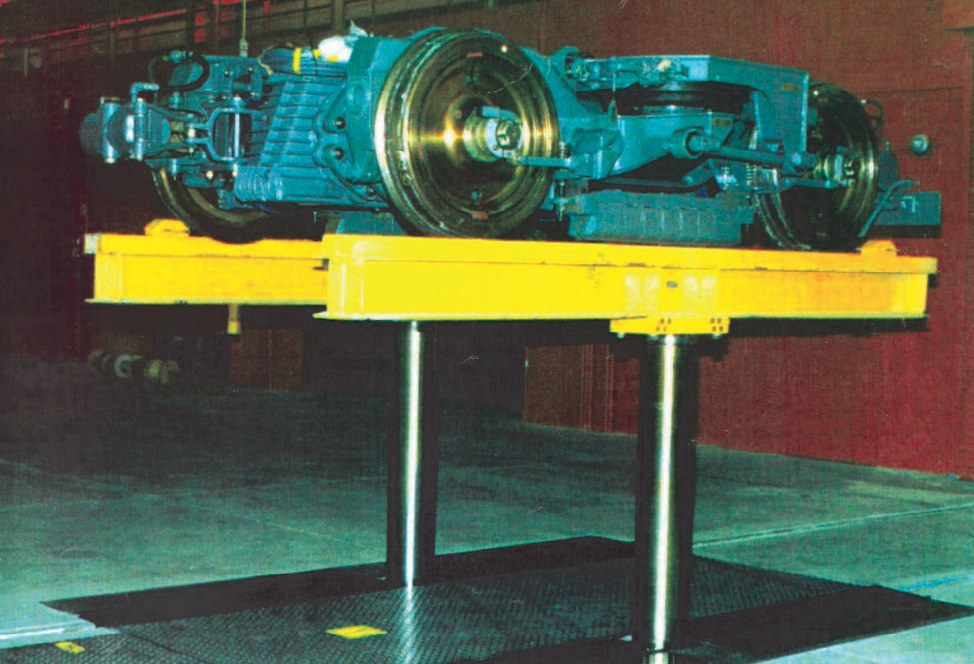

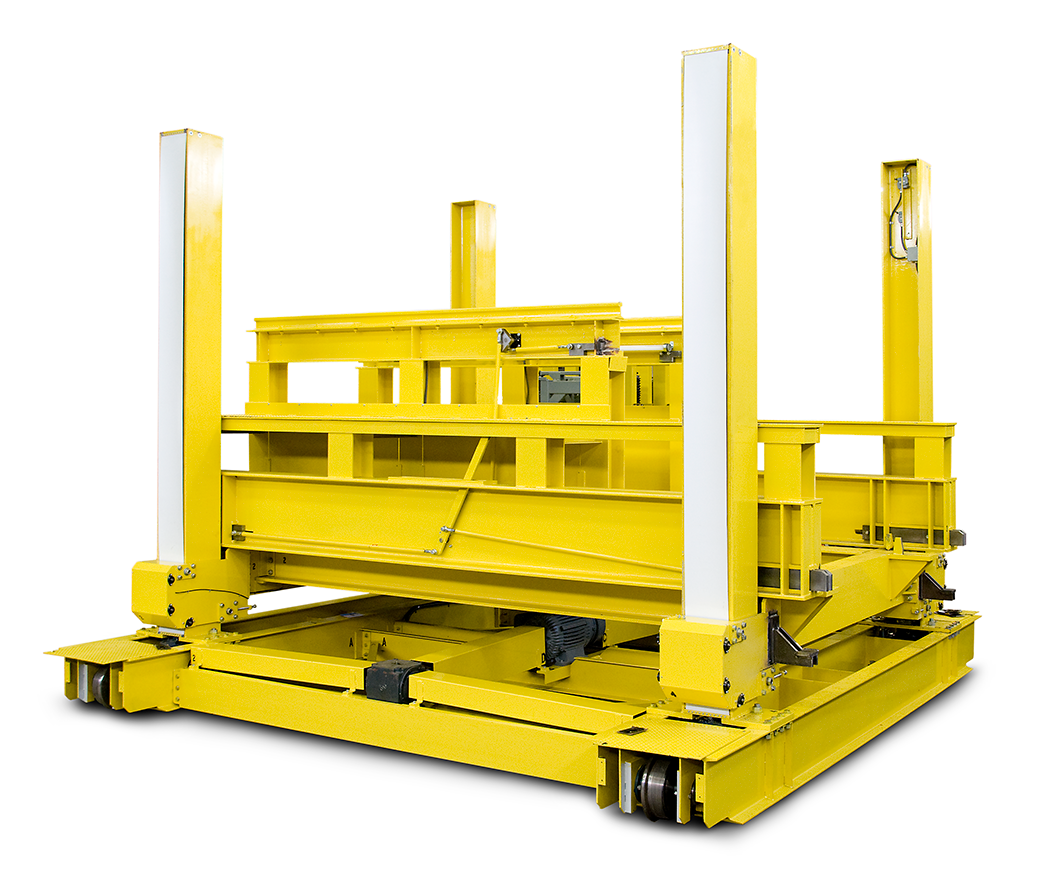

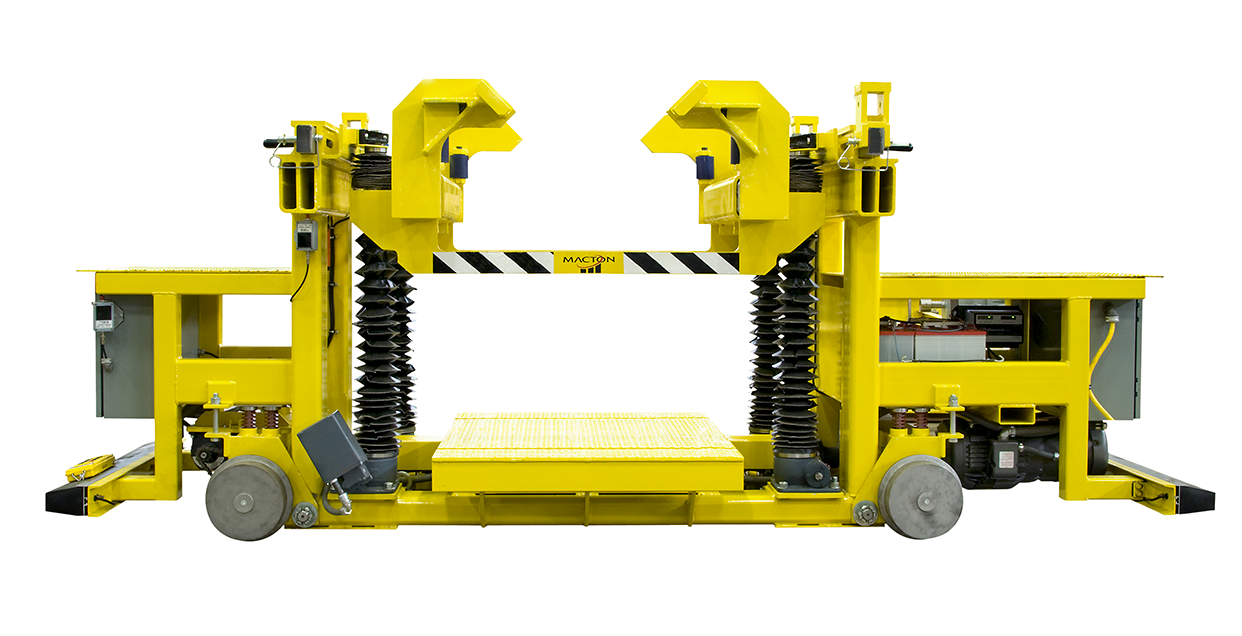

Macton offers a complete line of equipment to facilitate truck assembly maintenance and repair in the work shop. Macton car hoist systems may be used to remove a truck assembly from the railcar. The railcar is raised on the hoist, the car body is then supported by body stands or body hoists so that the truck may be disconnected and lowered to the shop rail. The truck may then be pushed to a truck turntable and rotated so that it can be transferred to a cross track and moved to the truck repair facility. When repaired, the truck may be returned to the car hoist and raised up to be re-attached to the railcar.

All Macton hoisting equipment is designed with mechanical screw jacking units with self-locking screw threads to ensure that the equipment will only raise and lower when power is applied to the motor. Macton recommends a shallow pit design for all hoisting equipment. The shallow pit foundations are generally less expensive to install because the pit depth is decreased from 20 feet to a nominal 3 1/2 feet. When hoists are installed in a shallow pit foundation, the screw and nut are housed in a caisson that protects them from damage caused by debris falling into the pit. The screw and nut are lubricated in a continuous oil bath extending the wear life of the screw and nut and decreasing the maintenance downtime for the equipment.

Specific Truck Removal Products Offered

There are a wide variety of products that Macton has to offer the transit system market, including the following: